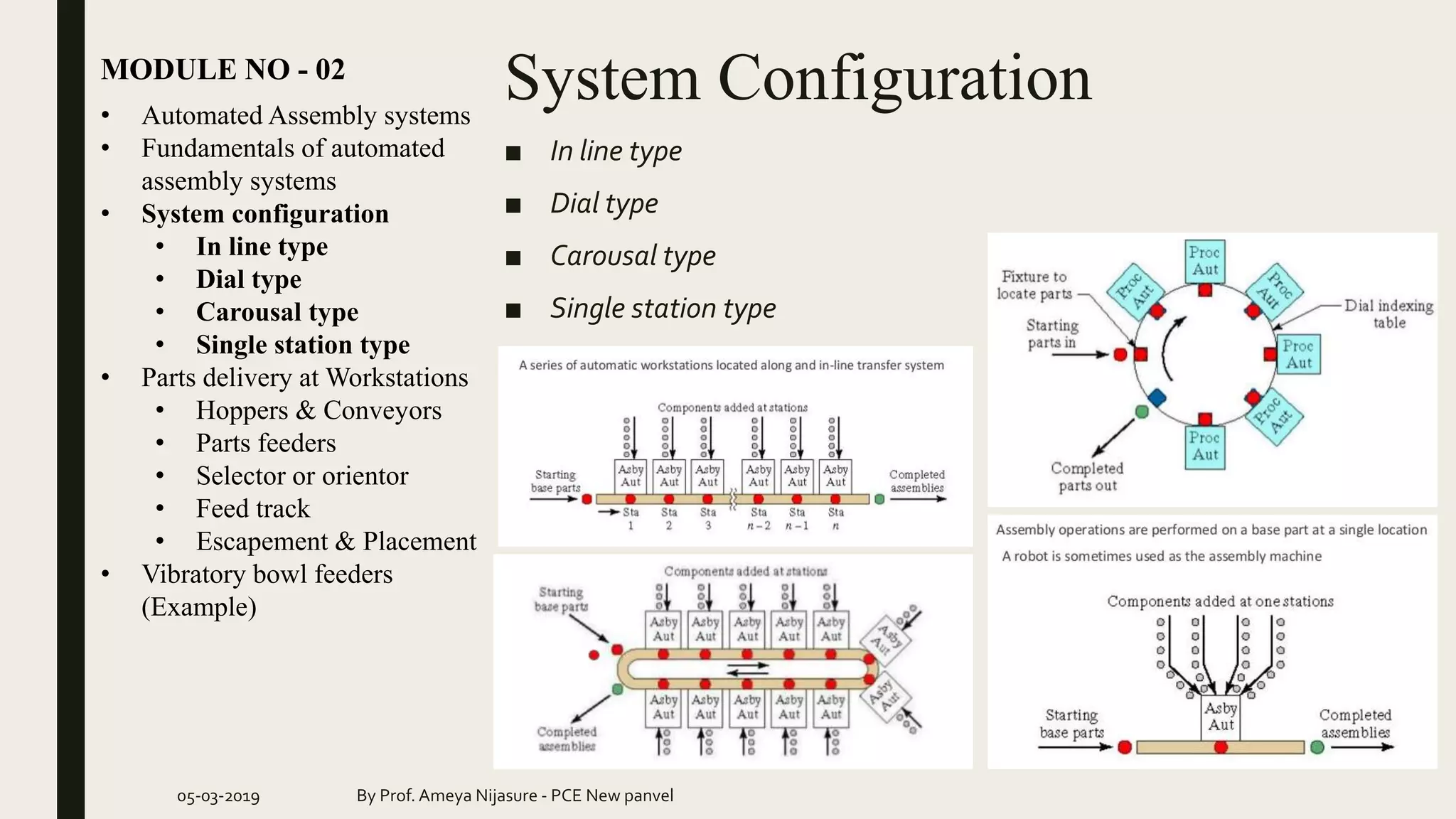

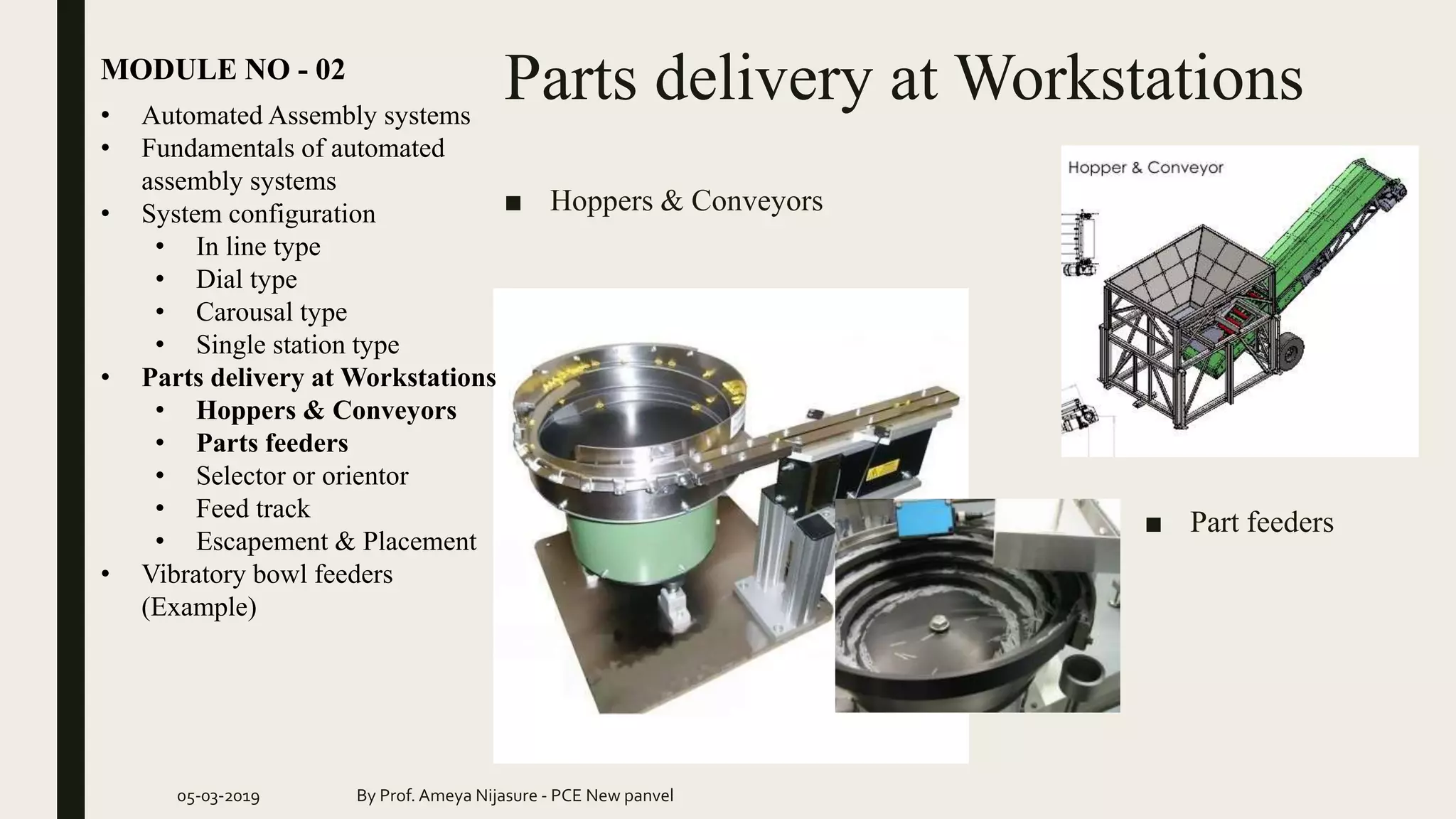

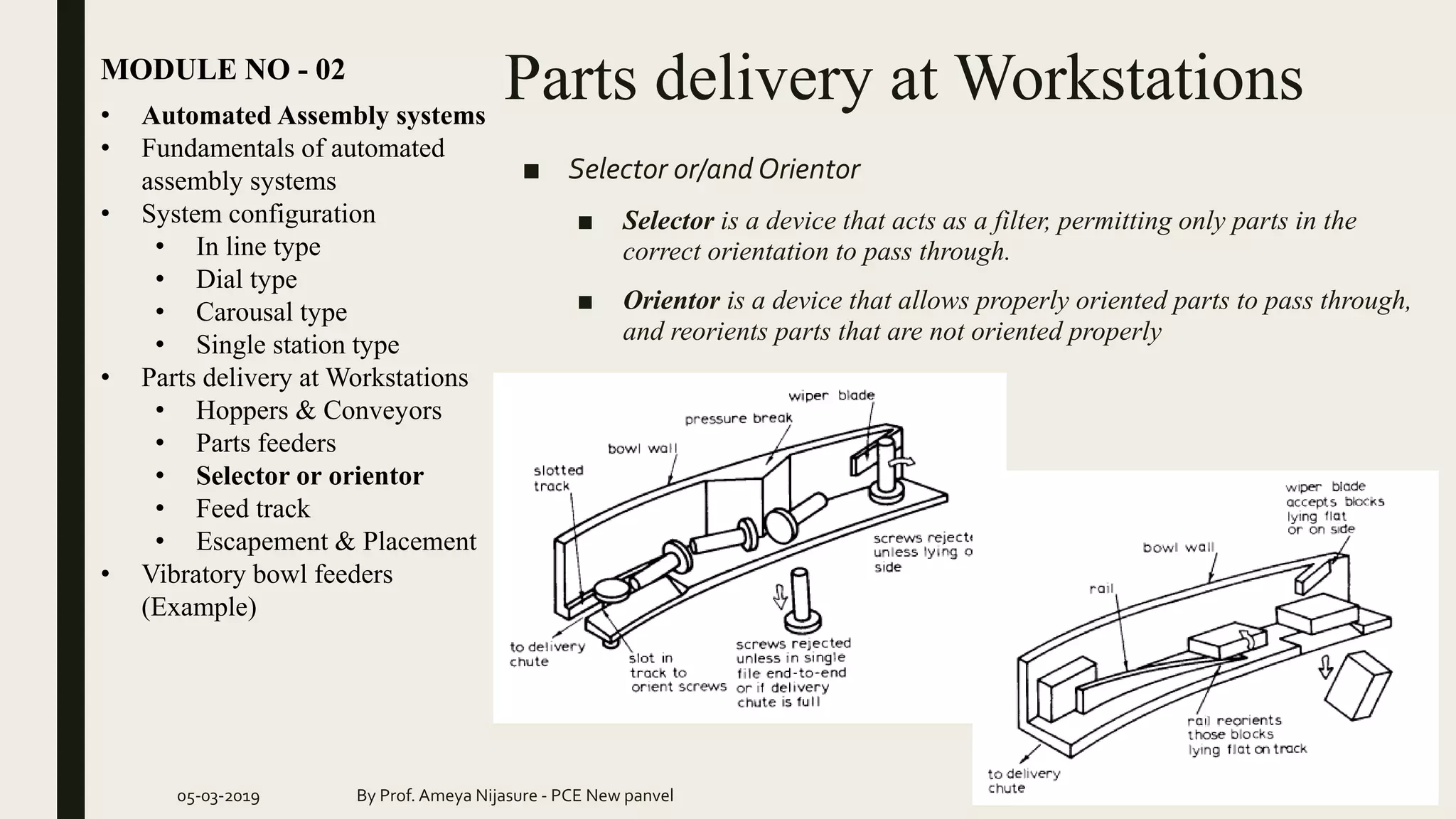

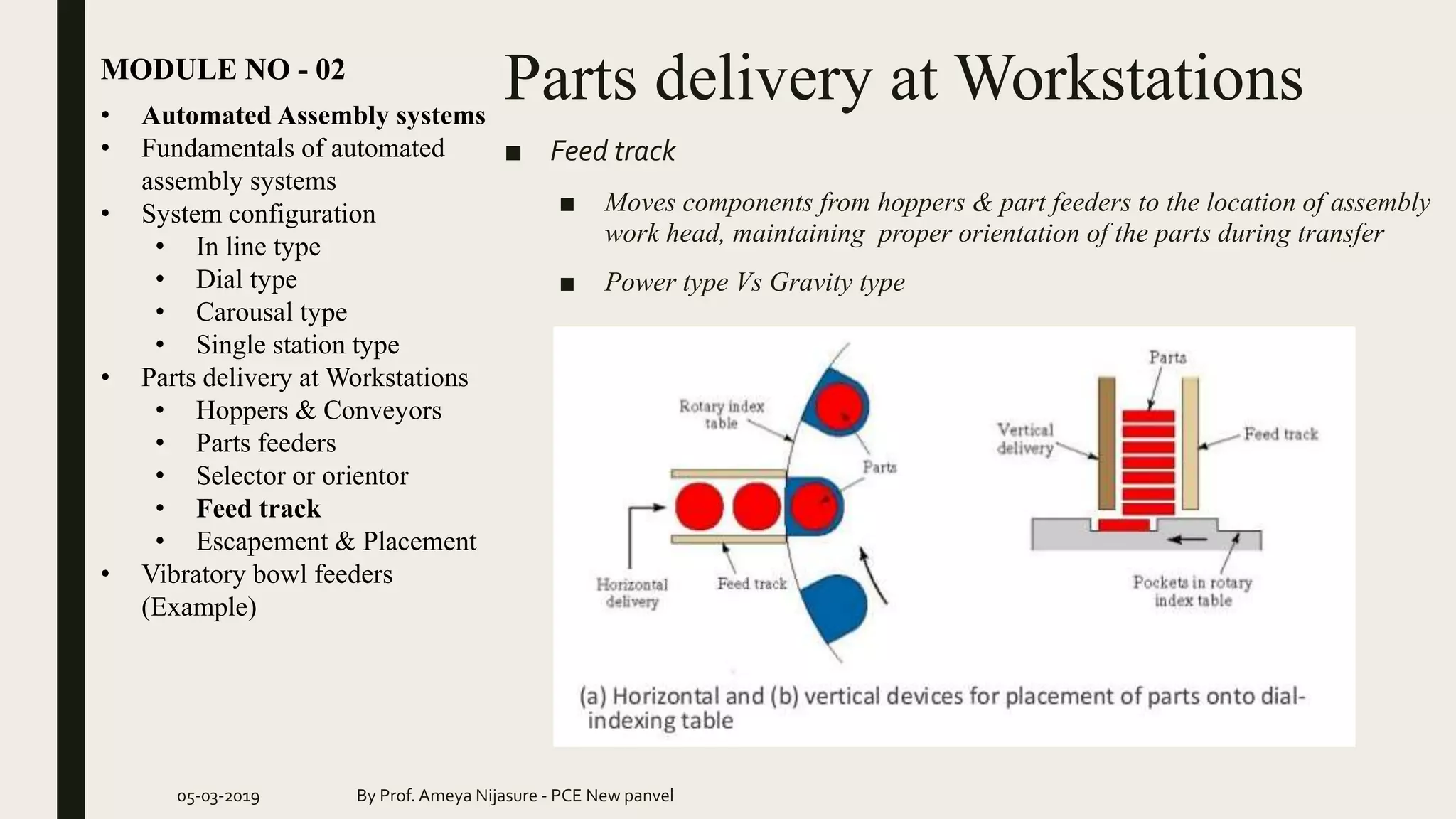

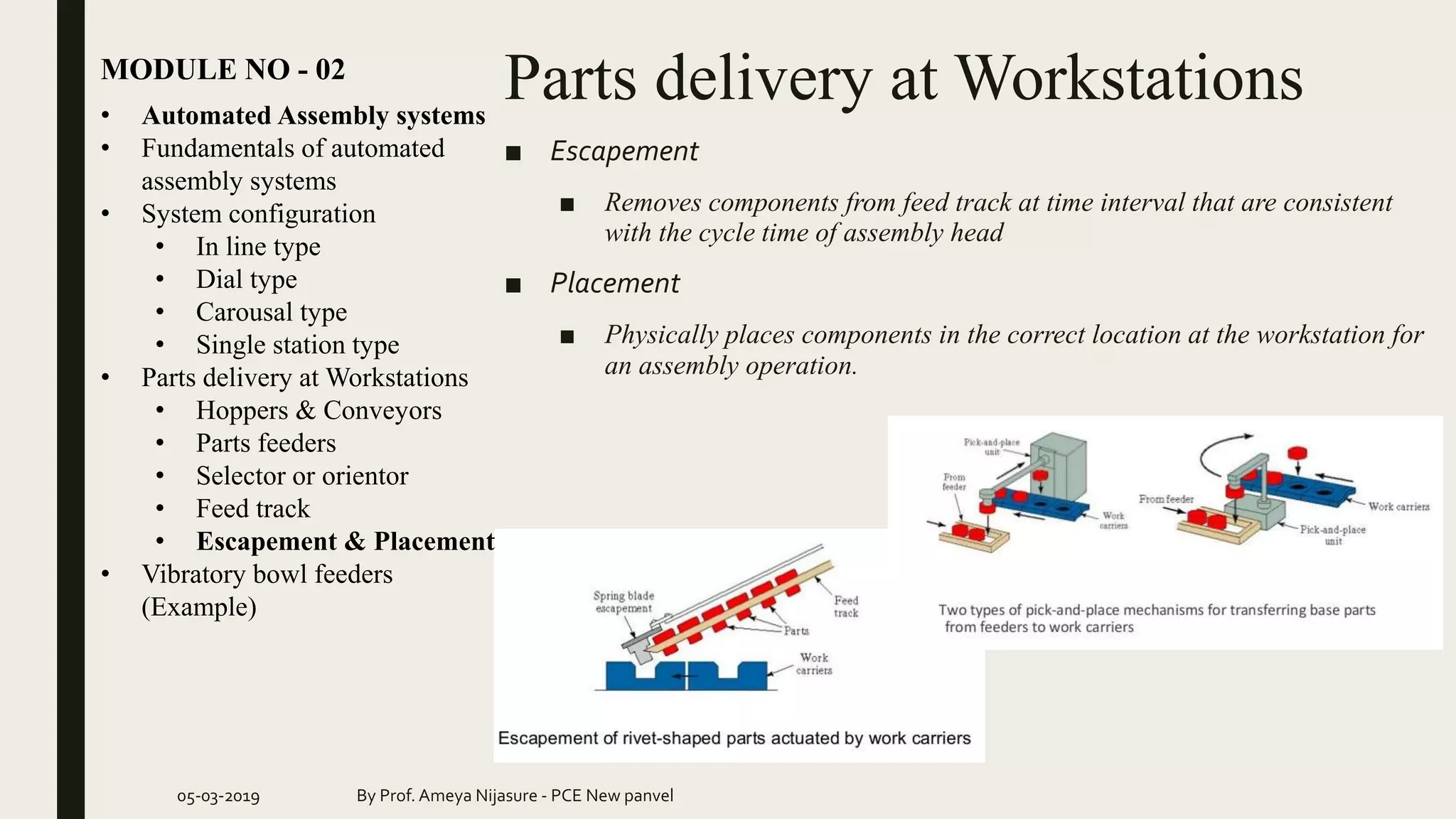

The document discusses automated assembly systems. It defines automated assembly systems as mechanized and automated devices that perform various assembly tasks. Automated assembly systems should be implemented when there is high product demand, stable product design, a limited number of components, and the product is designed for automation. The document describes different types of automated assembly systems like inline, dial, and carousel types. It also discusses subsystems of automated assembly like workstations, part feeding devices, and work handling systems. Finally, it explains various parts delivery methods and devices used at workstations like hoppers, conveyors, feeders, selectors, feed tracks, escapement, and vibratory bowl feeders.